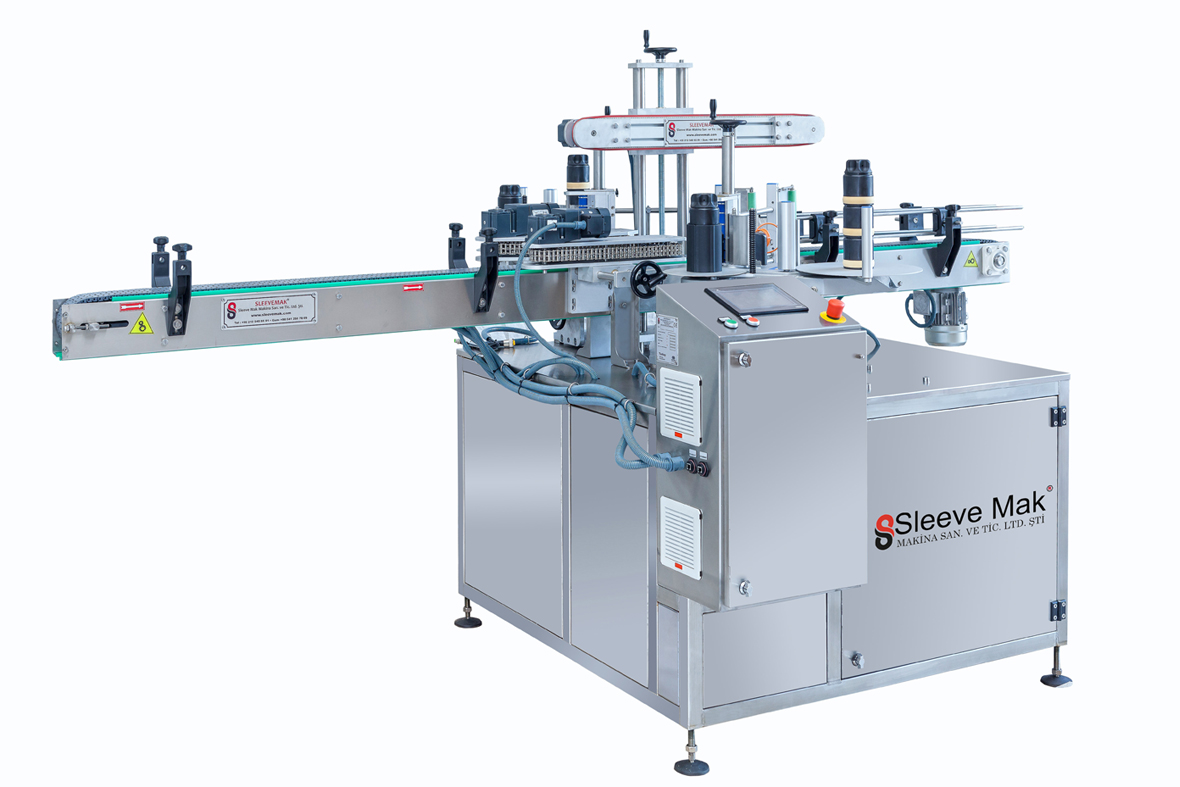

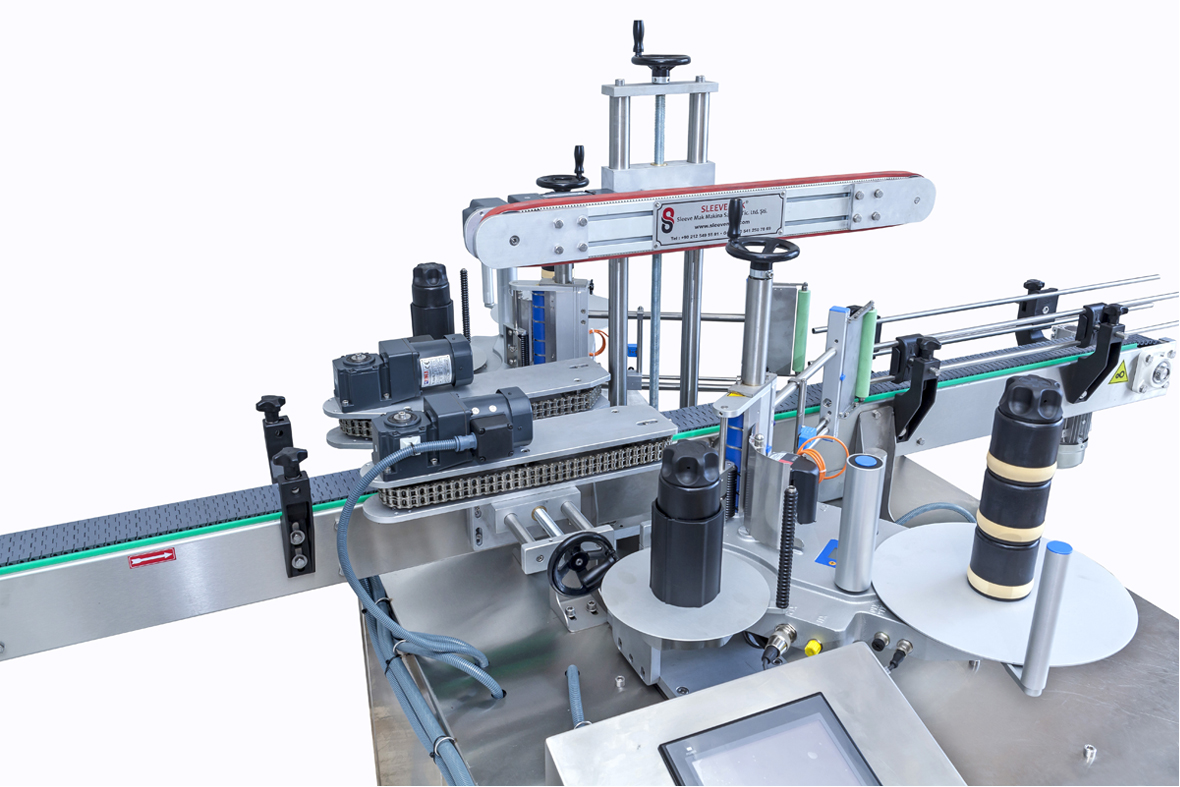

Double side labelling machine

Page Detail

Double side labelling machine

Double side labelling machine:

Model : SVM-LM0012

Technical specifications

- Our Main construction of the machine made from Stainless Steel AISI304, other parts made from aluminum

- Labelling process through linear line system.

- The machine can be synchronized with the automatic filling machine.

- the machine can work on cylinder , oval , square and rectangular shaped productss.

- Labelling Module ( German ) – two Module - (Type : Herma)

- Reducer motors ( Varvel-Italy)

Dual-sided labeling machine: A dual-sided labeling machine is a type of automatic labeling machine used in the packaging industry. This machine allows for the application of labels on both the front and back sides of packaging materials. These machines work efficiently and accurately, enabling optimization of production processes and efficient labeling operations.

Packaging labeling machine: A packaging labeling machine is a machine used to apply labels to packaged products. These machines typically operate automatically and have the ability to adapt to different shapes and sizes of packaging. Packaging labeling machines accelerate production processes, reduce human errors, and perform labeling operations with high precision.

Two-way labeling machines: Two-way labeling machines are machines that can apply labels to both the front and back sides of packaging. These machines automatically perform dual-sided labeling operations and enhance efficiency in packaging production lines. Two-way labeling machines are often designed to operate at high speeds and accommodate various sizes of packaging.

Double-sided labeling machine: A double-sided labeling machine is a machine that applies labels to both sides of packaging. These machines equip packaging with labels on both the front and back sides. Double-sided labeling machines accelerate production processes, ensure consistency in labeling operations, and enhance the aesthetic appearance of packaging.

Packaging industry labeling machines: Packaging industry labeling machines are specially designed machines used in food, beverage, pharmaceutical, cosmetic, and other packaging-focused sectors. These machines ensure accurate placement of labels on packaging and improve production line efficiency. Packaging industry labeling machines can be designed to accommodate different packaging types, sizes, and materials, and they often operate at high speeds.

Automatic labeling machine: An automatic labeling machine is a machine that automatically applies labels to packaging. These machines typically handle processes such as label feeding, adhesive application, and placement automatically. Automatic labeling machines operate at high speeds, provide high precision, and minimize human errors.

Labeling solutions: Labeling solutions refer to systems and machines designed to meet various labeling needs. These solutions are tailored to address labeling requirements in the packaging industry. Labeling solutions can include machines that operate automatically or semi-automatically, providing compatibility and flexibility for different sizes of packaging.

High-speed labeling machine: A high-speed labeling machine is a machine that applies labels to packaging at a high rate. These machines reduce processing time in production lines and enable rapid labeling of large quantities of products. High-speed labeling machines incorporate features such as precise sensors, fast adhesive mechanisms, and automatic label feeding systems.

Dual-direction packaging labeling machine: A dual-direction packaging labeling machine is a machine that applies labels to both sides of packaging. These machines ensure the accurate and consistent placement of labels on the front and back sides of packaging. Dual-direction packaging labeling machines automate labeling processes in the packaging industry and improve production line efficiency.

Semi-automatic labeling machine: A semi-automatic labeling machine is a machine that requires operator intervention. These machines typically operate based on the principle of manually taking labels and applying them to packaging. An operator prepares the packaging where the label will be placed and positions it on the machine. The machine then takes the label and applies it to the packaging. Semi-automatic labeling machines are suitable for businesses with lower production volumes or specific labeling requirements.

Industrial labeling machine: An industrial labeling machine is a robust and durable machine typically used in large-scale manufacturing facilities. These machines have the ability to operate at high speeds continuously. Industrial labeling machines enable the rapid application of labels onto packaging and optimize production processes.

Packaging production line labeling machines: Packaging production line labeling machines are machines that automatically label packaging within the production line. These machines can often operate at high speeds and accurately place labels on packaging. Packaging production line labeling machines facilitate fast and efficient labeling in the packaging process, reduce human errors, and enhance production line efficiency.

Share

Product Information

| Size: | |

|---|---|

| Colors | |

| Material |

Sleevemak Machinery Industry